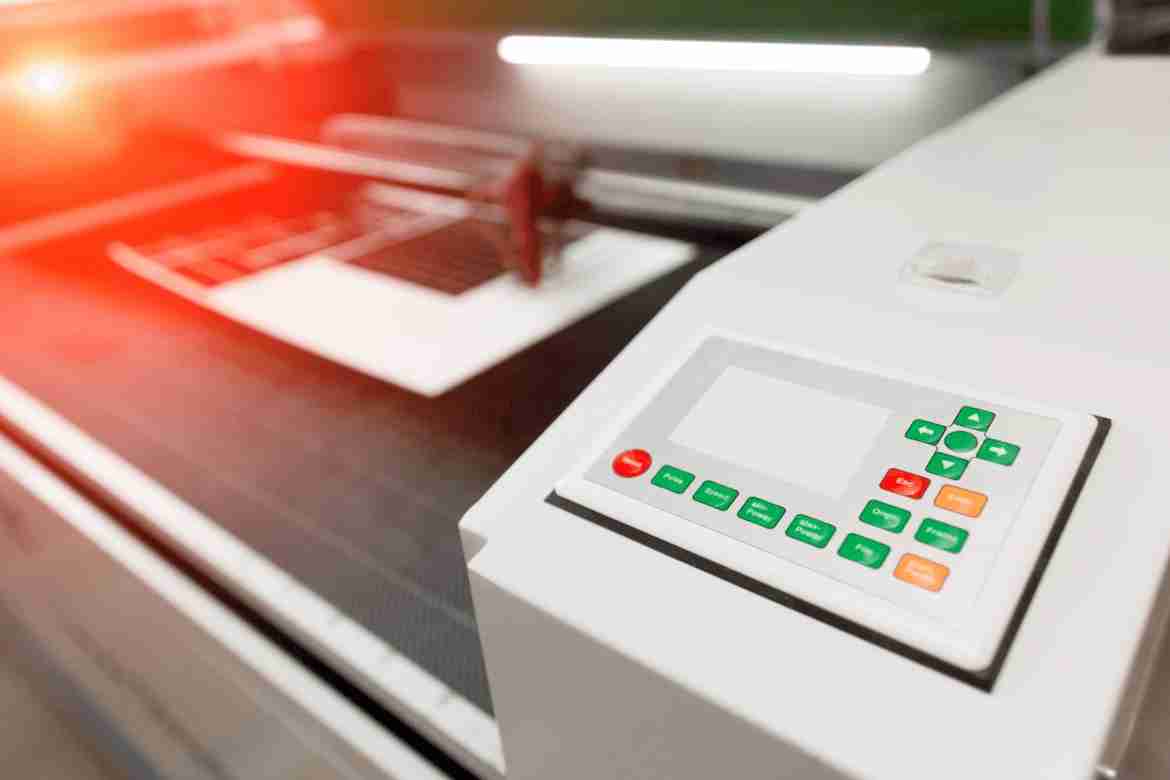

Laser engraving involves the use of a high-powered laser to physically remove areas of the surface of a part with high precision by use of CNC (Computer Numerical Controlled) technology. Engraving leaves a desired marking on the part that is visible to the eye.

Laser engraving presents a permanent marking technique at a low cost, with accurate and repeatable results on a large variety of surfaces and materials. It has become a popular customization solution choice over the years and has remained steady in terms of popularity.

As with any technology, its potential use cases and end-users have various options to fulfill that need. In this article we will be looking at most of these options, as well as the pricing and costs associated with each.

Pricing of laser engraving services: Online vs local

Laser engraving itself is a relatively inexpensive procedure for what it achieves. Almost all other engraving techniques would cost more than CNC laser engraving for the same detail, accuracy and precision.

For most people, it simply wouldn’t make sense to own a CNC laser engraver. There just wouldn’t be frequent enough use for it to justify the investment.

As such, we start looking at the pricing data by focusing on online laser engraving services.

These services generally provide flexible billing options based upon the size, complexity of the item to be engraved, and usually serve as a relatively cheap option for laser engraving needs for infrequent use.

A much bigger contributor to the total cost of laser engraving services are the shipping fees that would usually be involved in sending and receiving one’s article for engraving.

Along with referring to our guide below, it may be a good idea to consult your local area CNC or machine shops, as well as public colleges and universities and maybe even that DIY enthusiast friend or neighbor you may know.

Provided that they can handle the complexity, you would most certainly get a better overall rate as well as delivery time than opting for an online service.

Laser engraving cost: online services

The list we have gathered is by no means exhaustive. The nature of laser engraving technology is such that it would be nigh impossible to cover every single service provider on the web.

We have instead, collected a brief list of laser engraving service providers, to serve as a ballpark pricing reference for others searching for the best value laser engraving services or those looking to provide an engraving service of their own.

Pricing: $6 to $200 and above (discounts available on demand).

Services offered: Laser engraving, laser etching, deep engraving, other CNC machining services.

Materials covered: Trophy Plaques, fashion jewelry, silver and other metals, rings, precious metals, industrial parts, custom parts and others.

Notable for: Diverse and high-quality range of services available

Standard Turnaround time: 1 week

Pricing: $10 for first word/symbol and above (usually $3 per addition)

Services offered: Laser engraving, personalized embroidery

Materials covered: Various items of small personal nature.

Notable for: Free engraving services on clearance sales, in-depth personalization guide with logos, fonts, designs etc. to choose from. Multiple branches in North America

Standard Turnaround time: Up to 1 week

3. LASER-CUTZ

Pricing: $220 per hour for small CO2 or Fiber Laser Jobs, minimum charge $250 for small runs.

Services offered: Laser engraving, laser cutting, CNC, FDM Printing, Rapid Prototyping.

Materials covered: All materials that can be used with CO2 or Fiber Laser engraving

Notable for: Time-based billing suitable for bulk projects, flat rates also offered on negotiation basis.

Standard Turnaround time: 2-5 days (first in first out basis for job scheduling)

4. Ponoko

Pricing: $1 and upward per piece for bulk, $18 and up for single items

Services offered: Laser engraving and Laser Cutting

Materials covered: All materials available on their website, over 99 of them.

Notable for: End-to-end instant online quotation as well as product design assistance. Transparent pricing. Remake Guarantee.

Standard Turnaround time: 1 week

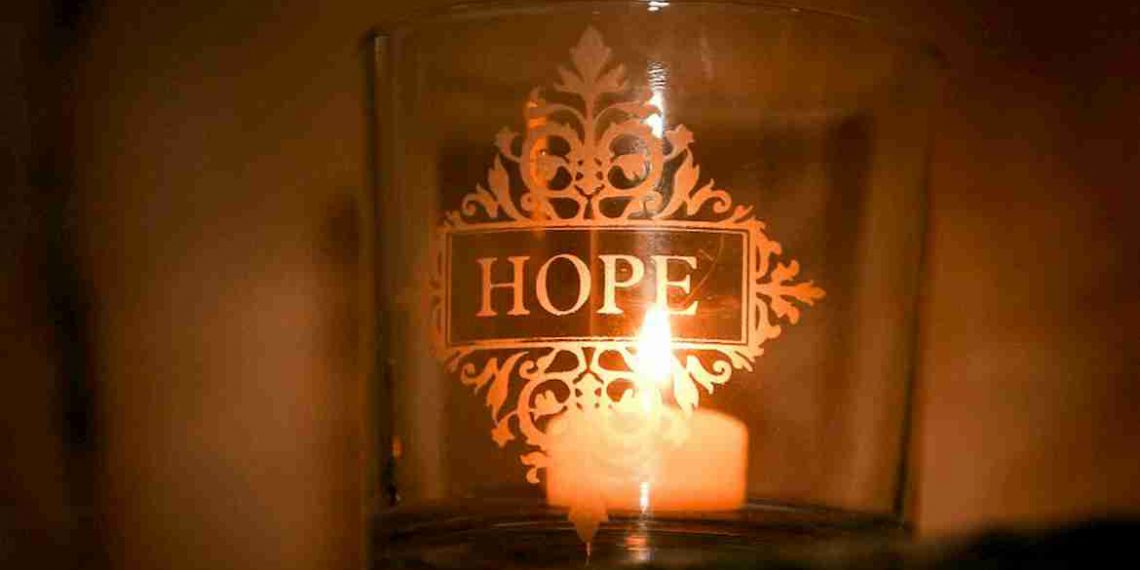

Pricing: $8 to $25 set-up cost, 0.45 Cents per letter engraved

Services offered: Laser engraving, rotary and stencil engraving also available.

Materials covered: Metals, plastics, glass, acrylic and others.

Notable for: Specializes in Trophies, cups and other “recognition” assortments. Economical rates.

Standard Turnaround time: Not provided, contact for more information.

Pricing: $75 per hour

Services offered: Laser engraving, Laser Cutting

Materials covered: Plastics, glass, acrylic and others.

Notable for: DIYers welcome to operate the laser, references / demonstrable knowledge of laser operation required.

Standard Turnaround time: Dependent on project.

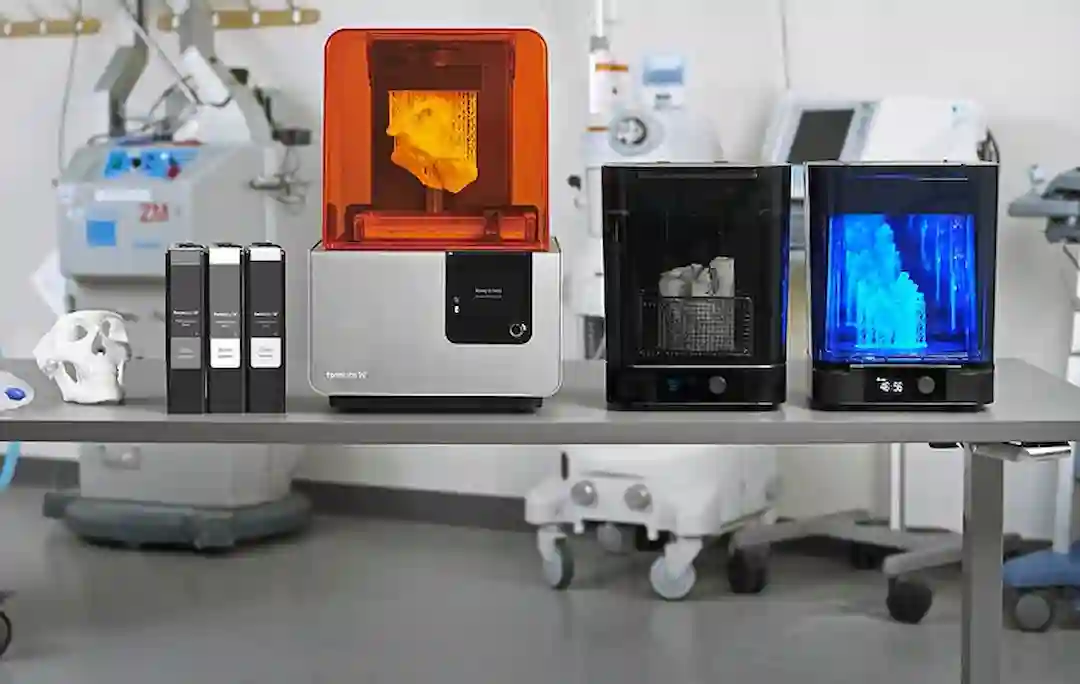

Buying a laser engraving machine

The decision to buy a laser engraving machine should be made on the basis of a number of factors.

While there are plenty of ‘desktop’ laser engraving machines nowadays, the fact remains that laser engraving machines in the consumer price range would not produce professional grade results as available with engraving services.

There is also the learning curve attached with operating a laser engraving machine, as well as processing and preparing the engraving image or logo etc.

Among other things, at the very least one should consider:

- The frequency of one’s laser engraving projects.

- Physical space available for a laser engraving machine.

- Ventilation and exhaust in the room.

- Free time for periodic maintenance of the machine, as well as for learning the ins and outs of laser engraving and the associated software (CorelDraw or other) and processing skills.

- Possible materials.

- And perhaps most importantly, the budget and the demands from the quality of the laser engraving (whether consumer level would suffice, or professional grade quality is a must)

Types of laser engraving lasers

While there are many different ways to classify laser engravers based upon their design, function or specialty, arguably the one factor affecting the cost of laser engraving is the type of laser used.

Co2-based lasers

Laser engravers with CO2 based gas lasers tend to be highly efficient with consistently intense laser beams. This in addition to their economical nature makes them the most popular type of Laser engravers available.

CO2 laser engravers are most suited for engraving non-metallic materials such as plastics, foils, stone, acrylics and organic materials like wood, paper, textiles, leather, and other similar materials.

Fiber lasers

Laser engravers with fiber based solid state lasers are known for their extreme precision and accuracy.

While being more expensive than CO2 lasers, fiber lasers offer up to 100 times the intensity and hence, accuracy and precision as compared to their CO2 counterparts for the same wattage.

Additionally, due to their solid-state, fiber lasers are maintenance free and last the longest number of service hours before needing eventual replacement.

Fiber based lasers are most suited for metal engravings of all kinds as well as for durable hard plastics.

Crystal lasers

Crystal lasers are also solid-state lasers with precision comparable to fiber lasers. The key differentiating factor for crystal lasers over fiber is their accuracy.

Crystal based lasers use ‘pump diodes’ that need to be replaced once they wear down and this makes these lasers the pricier of options to use for one’s laser engraving needs.

But if fiber-based lasers just aren’t cutting (or engraving) it for your project in terms of accuracy, these crystal lasers have a good shot of meeting those lofty needs.

Similar to fiber lasers, crystal lasers are also best suited for metals and hard plastics, with the addition of some ceramics (provided their surface allows for high intensity engraving).

Laser engraving machine pricing

Laser engraving machines can be bought these days foras little as $70 for something out of China, like the NEJE DK-8-KZ with its wood and leather engraving 1-Watt CO2 laser.

Basic cylindrical laser engravers similarly can be bought for as little as $200. However, a machine like this is much more a novelty gadget than a serious engraving tool.

CO2 based consumer laser engraving machines in the 40W plus laser strength range such as Mophorn 40 W Laser Engraver would set one back around $350 to $400.

Similarly, a CO2 based 100-Watt laser engraving machine at a minimum would cost around $1,000.

Whereas professional grade laser engravers go in the range of $2,000 up to $6,000 and above for CO2 and Fiber laser options. Diode-based lasers produce much better and repeatably accurate results however the premium in price is also something to consider.

The cost of building your own DIY laser engraver

The third gateway to laser engraving is of course, to do it yourself. As with all DIY projects, this most certainly is not for the faint of heart.

As a litmus test, if you do not find yourself ready to buy and operate your own laser engraving machine, you most certainly would shy away from the shop skills of building a DIY laser engraver.

That’s not to say it isn’t a rewarding experience. As with any DIY project, it should be approached with an open mind and buckets of free time.

The cheapest and simplest DIY laser engravers can be prepared from PC scraps – DVD burner drives in particulars. The cost here is simply the Arduino uno or nano board, some basic shielding and the power source.

Don’t expect a DVD burning laser to engrave anything more than cardstock or something similar at most.

Total costs would not go above $50 in any case. A good step by guide for such project is DVD Drive Laser Engraver (by Aoshido).

Moving a step up from the DVD laser engravers. This design is available with a complete bill of materials by MichielD99, which for him equated to a total cost of 208 euros or about $236. The project can be found here: Wooden DIY Laser Engraver (by MichielD99).

The design itself consists of wooden panels which can be substituted for hard plastic or even sheet metal.

The laser diode is a 5.5-Watt model. So, if a higher-powered laser is required that would add to the bill of materials.

For reference, individual CO2 laser modules range in price from $50 to $400 and above for different wattages.

Also make sure to opt for the correct heatsink and cooling. Take note that this is an open-air design, which while being easier to cool, has more room ventilation needs than a closed chamber model.

Depending upon the laser diode used as well as some other material choices, total costs should range from the ~$240 for the exact instructions to around $600-800 depending upon the strength of the laser and building materials (metal over wood / MDF).

Pros and cons of DIY laser engravers

The fun thing about DIY projects is they are what one makes of them. While certainly a cheaper option than buying a professional model. One area where DIY projects tend to fall short is long-term durability and ease-of-use.

For professional use-cases, professional equipment or at the very least, equipment that comes with a service warranty would probably work best.

But for tinkerers, hobbyists, and DIYers of all kinds, building it yourself is more than half the fun.

As a general rule, it would be difficult to compare DIY laser engravers’ engraving quality with that of prosumer or professional equipment. But if monetary budget constraints are the main considerations, then building a DIY laser engraver can easily save one a pretty penny at the cost of time and effort.

How laser engraving differs from other techniques

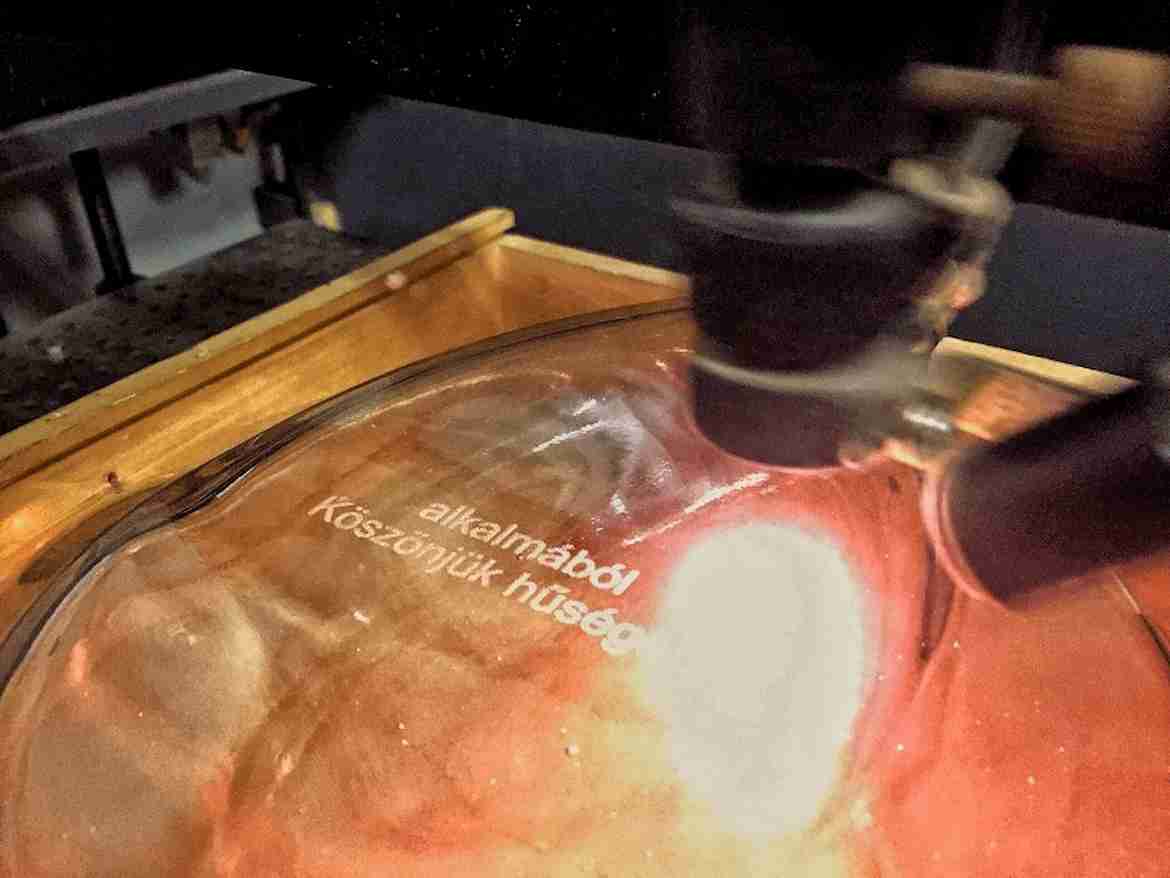

Laser engraving differs from other laser-based marking techniques such as the umbrella term, laser marking/coloring—as well as laser etching, in that laser marking involves the discoloration of the material surface to “print” a desired alphanumeric ID or a logo etc. Whereas with etching, instead of removing (vaporizing) the surface area, it melts the material surface in place in order to slightly raise or protrude the surface.

Another difference between laser engraving and other laser-based techniques is also the large number of materials that can be engraved. Whereas laser marking/coloring, along with laser etching have a limit to the materials that these techniques can be applied on.

Laser engraving can effectively be used on any surface and material such as metals, plastics, jewelry, wood, polymers and ceramics.

Whatever your particular case may be, we hope that this article would serve as a helpful guide in your laser engraving journey.

I’m glad that you explain that engraving machines that are within the consumer price range don’t give you professional-grade results. Since this is the case, it would probably be best to just work with a professional, especially if you need something more complicated like switchboard engraving. Researching professionals online should give you the chance to learn more about the available services to figure out which one has the experience and equipment to handle the work you need and also fits your budget.